Key Takeaways

- The integration of innovative technology into PVF systems enhances monitoring and maintenance.

- Material innovations improve durability and safety in various applications.

- Sustainability practices are increasingly influencing PVF manufacturing and usage.

Industrial operations today demand faster, safer, and more efficient solutions for pipeline systems that form the backbone of critical infrastructure. The pipe, valve, and fitting (PVF) sector has experienced dramatic advancements, becoming indispensable not only for traditional heavy industries but also for modern facilities like feed mills and advanced manufacturing plants. Innovation is driving a new era in which components are expected to deliver superior performance under challenging conditions. Suppliers such as Cruco Mill & Industrial Supply feed mill suppliers have become central partners in these efforts, ensuring industries receive the most reliable and innovative PVF products available.

Whether it’s constructing pipelines for water treatment, food processing plants, or energy transmission, modern PVF solutions are tailored to the specific challenges of different applications. The rapid integration of technologies such as IoT, along with progress in material science, is transforming how systems are designed, installed, and maintained. Companies are not only upgrading to more innovative infrastructures but are also focusing on long-term sustainability and operational resilience.

These shifts have produced a dynamic marketplace that values customization, longevity, and adaptability. PVF suppliers now act as collaborators, working closely with engineers and project managers to meet ever-evolving regulatory, technical, and environmental standards. Data-driven decision-making is increasingly fundamental for both real-time operations and strategic planning.

In this environment, understanding current trends and applications of the pipe, valve, and fitting supply can help operators maximize productivity, ensure compliance, and minimize long-term risk.

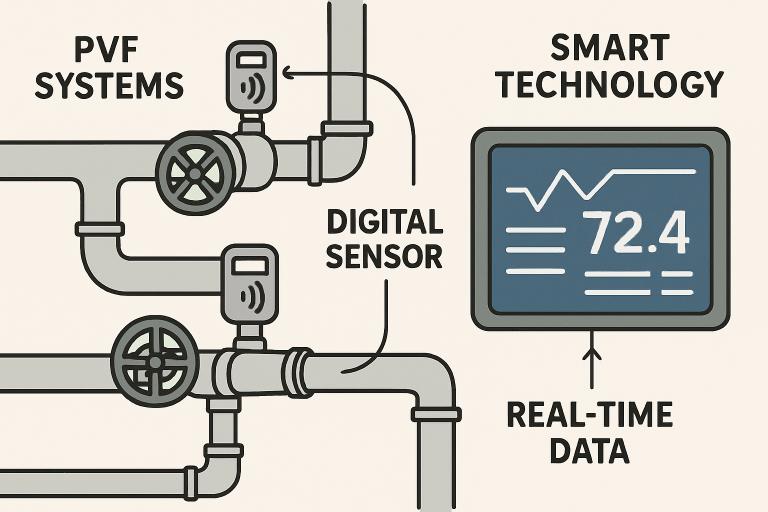

Smart Technology Integration

Advancements in Internet of Things (IoT) technology have been a game-changer for PVF systems. Modern pipelines frequently incorporate smart sensors that offer real-time insights into pressure, temperature, fluid composition, and leak detection. For instance, in healthcare settings like hospitals or food processing, such as feed mills, early warning systems automatically trigger maintenance alerts at the first sign of abnormal conditions. This capability not only prevents catastrophic failures but also significantly reduces operational downtime and repair costs. Widespread adoption of smart technology has made continuous data flow and remote system oversight the new standard.

Material Innovations

Material science breakthroughs are pushing PVF components well beyond conventional metals. High-density polyethylene (HDPE), cross-linked polyethylene (PEX), and advanced composite materials offer exceptional chemical and corrosion resistance, making them ideal for municipal water systems, chemical processing, and agriculture. These materials support higher pressure ratings and, due to reduced corrosion and scaling, reduce repair frequency. For industrial users, this means fewer interruptions and greater assurance in system longevity, which is particularly vital in power generation and biofuel manufacturing. Such material innovations are influencing regulatory standards and shaping best practices across industries.

Sustainability Practices

The PVF supply industry increasingly prioritizes environmentally friendly solutions. Manufacturers now adopt greener production processes, tapping renewable energy and minimizing waste. More suppliers are designing products with a focus on extended lifecycles and recyclability, aligning with corporate ESG mandates and regulations. Programs that collect, recycle, and repurpose old pipes and fittings demonstrate this commitment to a circular economy. These advances not only reduce carbon footprints but also future-proof infrastructures against tightening environmental regulations. Feed mills and industrial facilities actively seek out suppliers that can demonstrate robust sustainability credentials alongside technical expertise.

Enhanced Supply Chain Resilience

The global disruptions of recent years have exposed the vulnerabilities in traditional supply chains. In response, PVF suppliers are investing in local manufacturing, diversifying sources, and increasing inventory flexibility. For example, some leading providers have opened regional production facilities to shorten lead times and bolster reliability. These efforts ensure essential components remain accessible despite global shipping uncertainties and logistic bottlenecks. Additionally, closer-to-end-user warehousing allows for rapid deployment, minimizing project delays during peak construction or maintenance cycles.

Digitalization of Procurement Processes

As procurement moves increasingly online, PVF buyers now benefit from digital platforms that streamline everything from discovery to payment. Advanced search tools, tailored product recommendations, and automated reordering enable precise sourcing for complex bills of materials. This digital shift optimizes purchasing workflows for industrial users, enabling them to compare specifications and pricing in real time, manage inventory with integrated solutions, and access detailed documentation instantly. Enhanced transparency and speed not only improve buyer satisfaction but also reduce procurement costs—a key concern for large-scale operators.

Predictive Maintenance and Data Analytics

Predictive analytics is transforming PVF system maintenance. Smart sensors feed data into analytical platforms that identify early wear, corrosion, or flow inconsistencies. Maintenance teams receive actionable alerts, enabling interventions before costly breakdowns. This strategy helps companies achieve maximum uptime while extending the life of expensive infrastructure. With regulatory pressure increasing for safety and environmental stewardship, predictive maintenance ensures compliance and operational continuity. Real-world implementation of these strategies is growing, especially in energy and process industries, where unplanned outages can be extremely costly.

Conclusion

The rapid evolution of pipe, valve, and fitting supply reflects broader trends reshaping global infrastructure: digitalization, material innovation, and sustainability. By integrating smart technologies, leveraging advanced materials, and adopting greener practices, industry leaders are creating PVF solutions that meet the demands of today and tomorrow. Those who invest in these modern applications will find themselves better equipped to deliver safe, efficient, and reliable service—now and in the future. Staying ahead means not just adopting the latest technologies but choosing supply partners who understand the whole landscape of challenges and opportunities.