Key Takeaways

- Casters are essential for the smooth movement of goods, reducing physical strain on workers.

- Different types of casters serve specific functions, such as swivel casters for maneuverability and rigid casters for stability.

- High-quality casters contribute to workplace safety by preventing accidents and reducing noise levels.

- Advancements in caster technology, including motorized and air casters, are revolutionizing warehouse operations.

In the fast-paced world of warehouse operations, even small details can have a significant impact. Among the unsung heroes of material handling equipment, casters quietly enable the seamless flow of goods. While easily dismissed as basic wheels, casters facilitate efficient movement, reduce physical strain, and help optimize every corner of your warehouse. For those exploring equipment upgrades, heavy duty plate casters are an essential solution for safely handling large loads and improving maneuverability.

Casters are crucial for mobility and support strategic objectives, such as safety and productivity, in warehouses. They affect floor space, worker well-being, and operational flexibility, yet their importance is often underestimated in logistics planning. With various types available, including innovative motorized options, proper selection and maintenance can enhance efficiency and profitability. As supply chain demands grow, casters emerge as an overlooked yet essential competitive advantage, directly linking quality to safety, performance, and operational longevity.

Importance of Casters in Warehouses

Casters form the backbone of efficient warehouse movement. Whether installed on carts, racks, or machinery, they enable the movement of heavy items with minimal effort, directly impacting workflow speed and reducing worker fatigue. By simplifying item transport—from receiving to shipping—they play a key role in maximizing storage space and reducing downtime due to awkward or unsafe manual handling.

Their effectiveness in streamlining productivity is why leading logistics experts emphasize caster selection as a fundamental aspect of optimal warehouse design. Well-chosen casters enable businesses to quickly reconfigure layouts, thereby increasing throughput and making them a valuable asset for both operational and strategic planning.

Types of Casters and Their Applications

Selecting the correct type of caster is essential for meeting specific warehouse challenges:

- Swivel Casters:Provide 360-degree rotation, optimizing maneuverability in confined spaces or crowded aisles.

- Rigid Casters:Offer straightforward, stable movement, best for heavy loads traveling long, straight paths.

- Heavy-Duty Casters:Engineered for high load capacities, essential for safely transporting oversized pallets or industrial equipment.

- Low-Profile Casters:Keep necessary gear close to the ground without sacrificing mobility, minimizing tripping hazards.

- Rubber Casters:Cushion movements, reducing noise, and protecting sensitive floors from scratches and wear.

Each type is designed for unique operational needs. Versatility in caster choice enables warehouses to tailor solutions that match both the environment and task requirements.

Enhancing Safety with Proper Caster Selection

High-quality casters significantly mitigate the risk of accidents and facilitate a safer workplace. By decreasing push and pull force, they lower the chance of strain injuries—now a leading concern in industrial safety. Many modern casters feature locking brakes that stabilize equipment during loading or when not in use, helping prevent accidental rolling. Additionally, casters designed with vibration-dampening and noise-reducing features enhance comfort and communication on the warehouse floor, contributing to a safer and more productive environment. Reliable safety standards and regular staff training are key to maximizing the benefits of well-chosen casters.

Technological Advancements in Caster Design

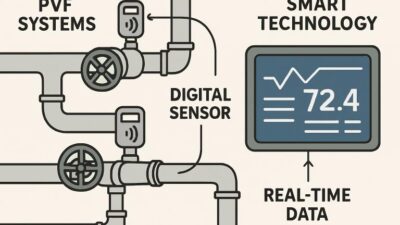

Caster technology has seen rapid innovation. Motorized casters, powered by electric drives, now enable even a single employee to move heavy machinery with ease—streamlining labor and reducing fatigue. Air casters, which create a thin cushion of air, allow heavy items to glide across the floor effortlessly, opening new possibilities for flexible, modular floor plans and enhanced safety.

The integration of smart sensors is also on the rise. These sensors can monitor load capacity, track usage, and deliver predictive maintenance alerts to preempt breakdowns, thereby reducing unexpected downtime and repair costs. Such smart handling equipment is transforming material flow management and safety protocols.

Impact of Casters on Warehouse Productivity

Quality casters drive measurable gains in productivity. Industry data indicates that switching from standard to high-quality heavy-duty casters can reduce downtime by up to 40% and maintenance costs by as much as 25%. Lighter push force requirements result in less physical fatigue and fewer worker injuries, ultimately benefiting the overall workforce health and efficiency.

Facilities that prioritize robust caster solutions frequently experience smoother workflows, fewer disruptions, and ultimately, greater customer satisfaction owing to reliable, on-time deliveries.

Maintenance and Longevity of Casters

Consistent inspection and maintenance are crucial to maintaining casters at peak performance. This includes routine lubrication, verifying that load ratings remain appropriate, and promptly replacing damaged units to minimize greater operational risks. A proactive approach helps extend caster lifespan and reduces the frequency of costly emergency repairs, safeguarding warehouse efficiency for the long term.

Workforce awareness is equally essential—training staff to identify early warning signs of caster wear or malfunction will preserve the quality of equipment and maintain a safe work environment.

Choosing the Right Casters for Your Warehouse

Selecting the most suitable casters for your application depends on multiple factors, including load capacity, floor conditions, and usage patterns. Consulting with material handling experts and exploring various reputable sources ensures the best fit for your warehouse needs. Resources from larger industry leaders can provide updated reviews and best practices to inform your purchase.

Conclusion

Casters are more than simple wheels; they are foundational to the efficiency, safety, and success of modern warehouses. By paying close attention to caster selection, embracing innovations, and maintaining them well, warehousing operations can unlock greater productivity and competitiveness, turning a once-overlooked detail into a powerful driver of long-term success.