Precast concrete services support projects that need durability, consistent quality, and faster scheduling than traditional site-poured methods often allow. Instead of forming and curing concrete entirely on the job site, precast components are produced in a controlled facility, then delivered and installed when the project is ready. This shift changes the construction rhythm: site work and concrete fabrication can occur simultaneously, weather delays can be reduced, and installation becomes more predictable because pieces arrive with consistent dimensions and finish standards. Precast is used across commercial, industrial, municipal, and residential applications, from structural panels and beams to utility vaults, steps, retaining elements, and drainage components. While each project has its own engineering needs, the overall advantage comes from combining material strength with repeatable production, allowing builders to maintain momentum and reduce rework caused by inconsistent onsite conditions.

From Factory to Jobsite

What Precast Concrete Services Include in Real Projects

Precast concrete services typically cover design coordination, fabrication, delivery logistics, and on-site placement of finished components. The process begins with specifications and shop drawings that translate engineering intent into production-ready details, including reinforcement layout, connection points, inserts, and lifting hardware. Because the pieces are created in a controlled environment, mixes, curing conditions, and finishing methods remain consistent, helping reduce common onsite issues such as surface defects and uneven curing. Services may also include custom formwork for unique architectural shapes, textured finishes, or embedded features such as conduit pathways and anchor plates. Many projects use precast to solve scheduling challenges because components can be produced while foundations and utilities are still being prepared. Contractors planning precast concrete services in Rock Island, TN often consider how plant fabrication can reduce downtime during seasonal rain or cold snaps that slow site-pour work. By the time the site is ready, the precast pieces can arrive staged for installation, allowing cranes and crews to place multiple components quickly in a single day.

Quality Control, Consistency, and Why the Factory Setting Matters

One of the biggest reasons builders choose precast is consistency. A factory environment allows tighter control over water-cement ratios, aggregate selection, admixture use, reinforcement placement, and curing cycles. This reduces variability that can occur when concrete is mixed and poured outdoors under shifting temperatures, wind, and humidity. Quality control checks can be built into each step: verifying rebar position, confirming embed placement, checking dimensions against shop drawings, and inspecting finish requirements before the piece ever leaves the facility. That consistency matters for both performance and fit. When components arrive on site with predictable tolerances, installation goes smoother, and connections align as planned. It also supports durability because well-controlled curing improves strength development and reduces the risk of cracking associated with uneven moisture loss. For owners, this can translate into fewer repairs and less long-term maintenance, especially for infrastructure elements that are constantly exposed to water or subjected to heavy loading. The controlled environment does not eliminate engineering requirements, but it provides contractors with a more reliable starting point for meeting them.

Speed and Sequencing Advantages Over Site-Poured Work

Precast changes the project schedule by separating fabrication from installation. While the job site team works on grading, foundations, and utilities, precast components can be produced simultaneously. This overlap can shorten overall timelines, especially for projects with many repeated elements, such as wall panels, structural members, or standardized vault systems. When pieces arrive, installation often becomes a “set and secure” process rather than a multi-day pour, finish, and cure sequence. That reduces the time crews spend waiting on concrete strength gain and lowers the risk of weather-related delays. Speed also affects labor planning because crane time, staging, and connection work can be scheduled with more precision. On tight sites, precast can reduce clutter by minimizing the need for extensive formwork, rebar storage, and on-site mixing. The scheduling advantage becomes especially noticeable when deadlines are fixed, such as commercial openings or municipal utility upgrades that must restore access quickly. When sequencing is planned well, precast supports a smoother build rhythm with fewer stop-and-start days.

Applications: Structural, Utility, and Site Solutions

Precast is not limited to one kind of project. Structural precast can include wall panels, columns, beams, hollow-core planks, and stair systems, which form major parts of a building’s frame. Utility and municipal precast often involves manholes, catch basins, lift station components, culverts, vaults, and box sections that manage drainage and underground infrastructure. Site solutions can include retaining walls, barriers, parking curbs, and protective bollard bases, with the goal of durable installation and predictable dimensions. Many precast pieces can be engineered to meet specific load requirements and environmental conditions, including exposure to salts, freeze-thaw cycles, or constant moisture. Because precast components are produced with embedded features, they can also support smoother installation for other trades, such as mounting points for railings, utilities, or equipment. The versatility comes from the material’s strength and the production process’s flexibility, allowing the same fundamental approach to serve both large public infrastructure and smaller commercial developments.

Installation Logistics: Transport, Cranage, and Jobsite Coordination

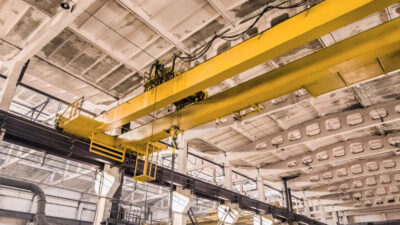

Precast requires careful logistics, and good services include planning for transport and placement. Components must be delivered in the correct sequence, stored safely if staging is required, and lifted using appropriate rigging that matches the piece’s engineered lifting points. Crane access, ground stability, and site clearance must be confirmed to ensure safe and efficient placement. Coordination also includes ensuring that foundations, embeds, and connection surfaces are prepared to match the precast shop drawings; even small deviations can slow installation or require field adjustments. Because precast pieces are heavy and precise, the jobsite team must treat placement like an assembly process, aligning components and securing connections according to engineering plans. When logistics are well managed, installation can be fast and clean, with fewer onsite variables than in a large pour. When logistics are poorly planned, delays can occur due to access limitations or missing prep work. That is why precast services often involve early coordination meetings to align the plant schedule with the jobsite readiness timeline.

Precast as a Strategy for Predictable Builds

Precast concrete services are often chosen because they make construction more predictable. By fabricating components in a controlled environment, teams gain consistent quality, tighter tolerances, and fewer weather-driven delays. The ability to produce pieces while site work continues can shorten timelines and reduce downtime, especially on projects with repeated elements or strict deadlines. Precast also supports a wide range of applications—from building structures to utility infrastructure—because components can be engineered for specific loads and exposure conditions. Success depends on coordination, particularly around shop drawings, transport scheduling, and installation planning, but when those pieces are aligned, precast becomes a practical strategy for building faster with fewer surprises. For many owners and contractors, that predictability is just as valuable as the concrete itself, because it protects budgets, schedules, and long-term performance.