Key Takeaways

- There are several core types of industrial compressors, each with distinct applications and advantages.

- Accurately assess your operational requirements, including air quality, pressure, and usage patterns, before selecting a compressor.

- Total cost of ownership, energy efficiency, and environmental considerations should drive your decision-making process.

Industrial compressors are crucial in various sectors, including food processing and pharmaceuticals, ensuring a steady supply of compressed air or gas essential for diverse operations. Making the right choice can significantly impact efficiency, cost management, and system reliability. By understanding what sets each compressor type apart and matching them to your facility’s demands, you optimize your workflow for the long run. For expert advice and high-quality compressor solutions, visit Cbeuptime.com. Working with the right compressor isn’t just about technical specs—it’s about maximizing uptime, reducing energy waste, and supporting your business goals. Careful consideration of operational needs, maintenance expectations, and safety requirements makes all the difference in day-to-day performance.

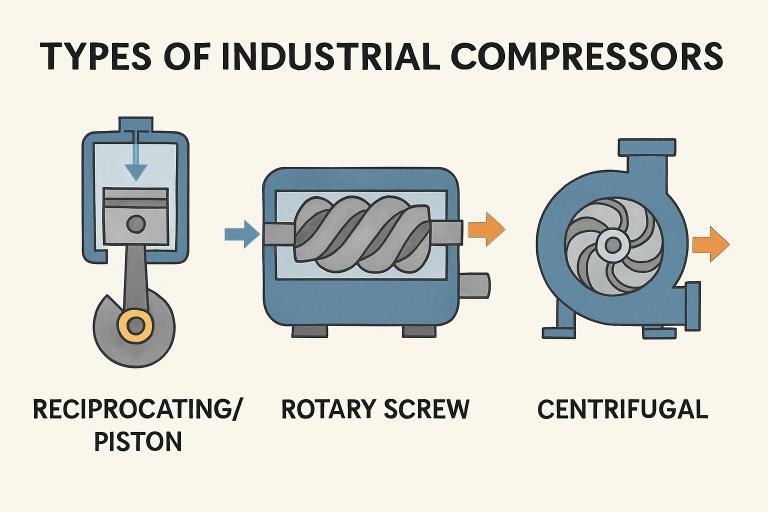

Understanding Compressor Types

Industrial compressors are engineered with differing mechanisms suited for varied environments and applications. Choosing intelligently can affect everything from operating costs to air quality standards.

- Reciprocating (Piston) Compressors:These compressors are often used for intermittent, high-pressure tasks such as workshops or small manufacturing plants. Their robust build makes them affordable and accessible, though they tend to need more routine maintenance due to their manual motion.

- Rotary Screw Compressors:Best suited for continuous-duty applications, rotary screw compressors supply steady airflow and operate with reduced vibration and noise. They’re a staple in large-scale manufacturing and critical operations where uptime is paramount.

- Centrifugal Compressors:Centrifugal, or turbo, compressors are designed for large, continuous operations such as petrochemical processing or industrial utilities. They provide exceptional energy efficiency for high-volume needs but come at a premium investment.

Your choice should always align with your facility’s scale and production cadence. Oversized compressors consume unnecessary energy, while undersized options lead to frequent downtime and compromised product quality.

Assessing Your Operational Requirements

Before making a purchase, thoroughly review the requirements of your application. These pre-purchase checks not only ensure peak performance but also help to safeguard product integrity, particularly in regulated sectors.

- Air Quality:Industries such as food and beverage, pharmaceuticals, and electronics require oil-free air to prevent contamination. Selecting oil-free or filtered compressors can prevent compliance issues and fines.

- Pressure and Flow Requirements:Identify your precise PSI (pounds per square inch) and CFM (cubic feet per minute) needs. An accurate calculation ensures your compressor delivers the necessary force and volume without strain.

- Duty Cycle:Define how much of the day your compressor will run. Intermittent tasks are well-matched to piston compressors, while continuous processes benefit from screw or centrifugal machines.

Carefully matching compressor output to demand can make a massive difference to operational costs and machine longevity.

Energy Efficiency and Total Cost of Ownership

Energy efficiency is a key factor in compressor selection, as it has a direct impact on both sustainability and bottom-line expenses. Efficient compressors can yield substantial energy savings—sometimes exceeding 30%—over less advanced models. Assess the unit’s energy use, maintenance intervals, and expected service life, as these collectively contribute to long-term cost savings. Another factor to consider is downtime. Compressors that are easier to maintain and service translate into fewer disruptions. Manufacturers typically provide data on average service intervals, parts cost, and downtime projections, allowing you to estimate the actual cost of ownership beyond the price tag.

Additional Considerations

Selecting a compressor extends well beyond capacity and efficiency. Consider the following to ensure your new unit seamlessly fits your workspace and operational flow:

- Environmental Conditions:Ensure your chosen compressor is rated for your facility’s ambient temperature and humidity. Extreme conditions may necessitate the use of specialized components or cooling systems.

- Space Constraints:Measure and verify available installation space, factoring in room for service personnel and ventilation requirements.

- Noise Levels:Exposure to high noise can harm workers and violate workplace regulations. Rotary screw compressors, for instance, are lauded for their quiet operation, making them preferable in proximity to workstations.

Compliance and environmental responsibility also carry increasing weight in purchasing decisions today. Innovations like variable-speed drives may require higher initial investment but generate worthwhile savings and emissions reductions in the long term.

Conclusion

Matching an industrial compressor to your application is an investment in efficiency and reliability. Begin with an in-depth assessment of operational requirements, then prioritize air quality, appropriate pressure and flow, and evaluate the maintenance and energy profiles of each type. Thoughtful selection ensures your compressor not only meets today’s demands but also supports future growth and compliance. By considering all technical, operational, and environmental factors, your business will reap long-term benefits and maintain a critical edge.