Heating and cooling systems represent a major investment for homes and businesses, yet many owners focus only on short-term performance rather than long-term durability. The role of HVAC contractors in extending equipment life cycles centers on preserving functionality while reducing unnecessary strain on critical components. Through careful observation, routine adjustments, and informed guidance, contractors help systems age more gradually. Longevity is not accidental; it results from consistent care that accounts for how equipment responds to daily use and environmental conditions. When systems are properly supported, they maintain comfort, efficiency, and reliability for years beyond average expectations through thoughtful stewardship.

Planning for Longevity

Understanding how systems age

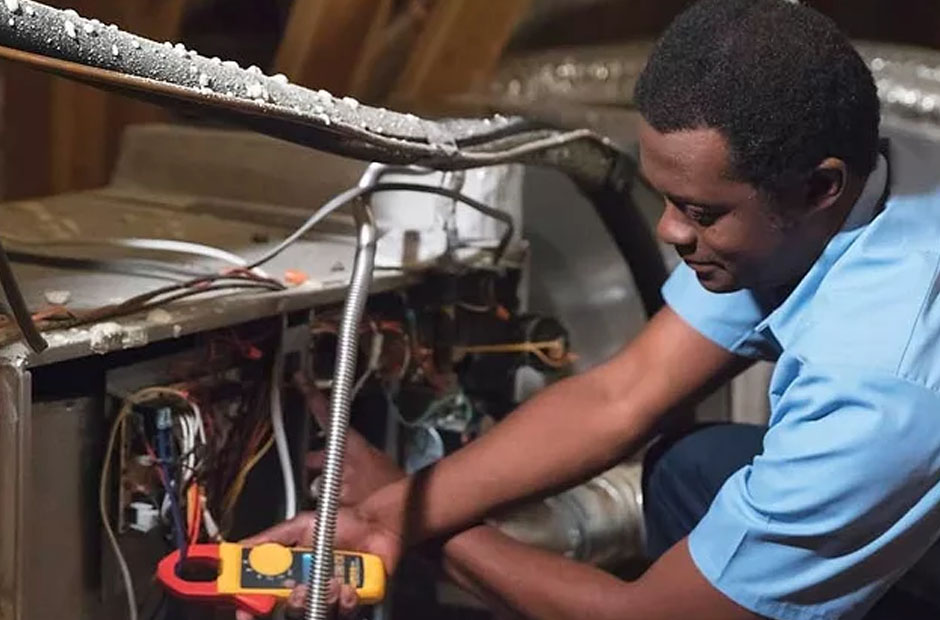

From the moment an HVAC system is installed, its long-term performance is shaped by how it is operated and maintained. Contractors focus on understanding how equipment responds to the specific environment in which it operates, including climate, building layout, and usage patterns. Early attention to airflow balance, electrical stability, and control settings helps prevent uneven wear that can shorten service life. In many service visits, contractors also evaluate connected equipment, such as water heaters, to ensure the overall mechanical setup functions harmoniously, which can influence decisions like water heater replacement in Canton when aging components begin affecting system balance. This holistic understanding enables contractors to guide owners toward practices that reduce equipment stress and promote steady operation over time.

Routine care as a longevity strategy

Routine service is not about constant repair but about maintaining stability as systems mature. HVAC contractors observe subtle changes in sound, cycling behavior, and temperature consistency that signal developing strain. Addressing these early helps prevent small issues from escalating into system-wide stress. Regular adjustments to belts, motors, and control components help maintain alignment and reduce friction. Contractors also monitor how often systems start and stop, since excessive cycling can accelerate wear. By focusing on these details during routine visits, contractors help systems maintain predictable performance, supporting a longer, more reliable service life without unnecessary intervention.

Midlife System Care

Midlife system care focuses on stabilizing performance once equipment has moved beyond early operation but remains structurally sound. At this stage, small inefficiencies can quietly accelerate wear if ignored. Contractors monitor run times, cycling behavior, and airflow balance to prevent cumulative stress. Consistent minor corrections help motors, compressors, and controls operate within their intended ranges. This phase is less about repair and more about preservation through attentiveness. By maintaining steady conditions and addressing deviations early, systems continue to deliver dependable comfort without unnecessary strain, allowing owners to defer major decisions while sustaining predictable operations and reducing premature replacement pressures across portfolios.

Managing environmental and usage factors

Environmental conditions and daily usage habits play a significant role in how long HVAC equipment lasts. Contractors consider factors such as dust levels, humidity, and temperature extremes that may strain systems. They also assess how occupants use the system, including thermostat habits and operating schedules. Systems that are constantly adjusted or pushed beyond intended ranges tend to age faster. By helping owners understand how everyday behavior affects equipment, contractors support more balanced usage. This alignment between environment, habits, and system design helps reduce unnecessary stress and supports consistent performance across changing seasons.

Documentation and long-term planning

Extending equipment life cycles requires continuity, which is supported through accurate documentation and long-term planning. HVAC contractors keep records of observed conditions, adjustments made, and performance trends over time. These records help identify gradual changes that might otherwise go unnoticed. With this historical context, contractors can recommend timely interventions that support longevity rather than reacting to sudden failures. Long-term planning also allows owners to prepare for eventual upgrades without disruption. This proactive approach ensures that decisions are informed by system history rather than urgency, reinforcing stability and extended service life.

Durability Through Consistent Care

Extending HVAC equipment life cycles is a deliberate process shaped by consistent care rather than isolated fixes. HVAC contractors contribute by observing system behavior, correcting imbalances, and guiding owners toward informed decisions over time. Their involvement reduces avoidable stress on components and supports steadier operation as systems age. When longevity becomes a priority, maintenance shifts from reaction to intention. This approach protects investments, minimizes disruption, and preserves comfort across seasons. By focusing on durability through attentive service, contractors help equipment remain reliable, functional, and valuable long after installation, reinforcing the importance of sustained stewardship in building performance for owners everywhere.